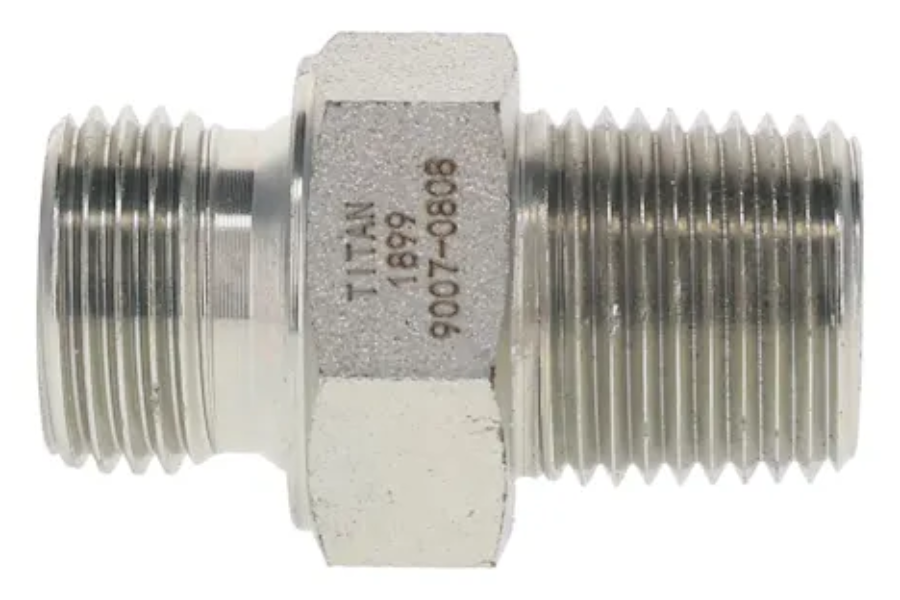

Understanding 9007BSPP to NPTF Fitting: A Comprehensive Guide

Introduction

In the realm of plumbing and hydraulic systems, using the correct type of fitting is essential for ensuring connections that are leak-proof, secure, and fully functional. Among the various types of fittings, the British Standard Pipe Parallel (BSPP) and the National Pipe Tapered Fuel (NPTF) are two of the most common thread types encountered. These standards are crucial for hydraulic systems, especially when adapting between British and American specifications. The 9007BSPP to NPTF fitting serves as a vital component, enabling seamless compatibility between these two standards. This article aims to delve into the specifics of the 9007BSPP to NPTF fitting, its applications, and its significance across multiple industries.

What is a BSPP Fitting?

BSPP, or British Standard Pipe Parallel, is a thread standard originating from the United Kingdom and is extensively utilized in Europe and other regions. One defining feature of BSPP fittings is their straight thread design, which contrasts with other types like British Standard Pipe Tapered (BSPT) or NPTF. The parallel threading allows for a reliable connection when complemented by additional seals, such as O-rings or washers, rather than relying solely on the threads to create a seal.

The 9007BSPP to NPTF fitting provides an essential function by enabling the connection of BSPP fittings to systems utilizing NPTF threads, which require different sealing mechanisms and thread designs.

What is NPTF Fitting?

NPTF stands for National Pipe Tapered Fuel, a thread standard commonly found in the United States. Unlike BSPP, NPTF fittings feature tapered threads, which means that the thread diameter decreases along the length of the fitting. A distinctive characteristic of NPTF fittings is their ability to create a dry seal. When two NPTF fittings are joined, their threads compress against one another to form a seal, eliminating the need for additional sealing materials like tape or sealants.

The 9007BSPP to NPTF fitting is particularly important for adapting components with BSPP threads to fit into NPTF systems, which is a frequent scenario when working with global hydraulic systems or machinery that is imported or exported.

The Importance of Thread Compatibility

Ensuring thread compatibility in hydraulic systems is critical. Using an incompatible fitting can lead to leaks, system failures, and serious safety risks. The 9007BSPP to NPTF fitting guarantees that components with British BSPP threads can be safely integrated into American NPTF systems, effectively bridging the gap between these two international standards.

With the proper 9007BSPP to NPTF fitting, engineers and technicians can create connections between components from different systems, which not only leads to efficient operations but also minimizes the risk of equipment damage. This fitting acts as a critical link, ensuring that both thread types can function together harmoniously within a single system.

Where 9007BSPP to NPTF Fittings Are Used

9007BSPP to NPTF fittings are commonly found in various industries, including manufacturing, automotive, and aerospace. These sectors often work with hydraulic and pneumatic systems that necessitate precise and reliable connections. Moreover, in global trade, European products frequently utilize BSPP fittings, while American products are typically designed with NPTF threads. The 9007BSPP to NPTF fitting ensures that these components are compatible, regardless of their country of origin.

Examples of applications include hydraulic machines, fuel systems, and plumbing setups that require the connection of parts with differing thread standards. The 9007BSPP to NPTF fitting allows these connections to be made without compromising the integrity of the system.

How 9007BSPP to NPTF Fittings Work

Fundamentally, the 9007BSPP to NPTF fitting functions as an adapter. One end of the fitting is equipped with BSPP threads designed to connect with British components, while the opposite end features NPTF threads meant for American components. This dual-thread design facilitates the smooth integration of various thread types within a single system.

When installing a 9007BSPP to NPTF fitting, users must ensure that all components are appropriately tightened to create a secure seal. The BSPP end typically requires additional sealing materials such as O-rings to achieve a leak-proof connection, whereas the NPTF end relies on its tapered design to create a dry seal.

Why the 9007BSPP to NPTF Fitting is Critical for Global Operations

In today’s interconnected global economy, machinery and equipment are often manufactured in one region and shipped to another. Each country has its own engineering standards, including specific thread types for pipes and fittings. For instance, equipment produced in Europe might use BSPP fittings, while infrastructure in the United States commonly employs NPTF threads. The 9007BSPP to NPTF fitting plays a crucial role in ensuring that these international products can work together without complications, effectively eliminating the need for expensive retrofits or replacements.

By utilizing the 9007BSPP to NPTF fitting, companies can save both time and money by adapting existing equipment instead of investing in entirely new machinery. This fitting is especially valuable for engineers and technicians who operate in multinational industries, where compatibility is paramount.

Common Issues with Thread Conversion

While the 9007BSPP to NPTF fitting offers a convenient solution for thread conversion, it is not devoid of challenges. One prevalent issue is ensuring the fitting is installed correctly. Misalignment of threads or improper tightening can lead to leaks or system failures.

Furthermore, it is crucial to use the correct sealing materials. The NPTF end of the fitting does not require additional sealants, but the BSPP end typically does. Utilizing the wrong type of O-ring or sealant can jeopardize the connection, resulting in costly repairs or system downtime.

Materials Used in 9007BSPP to NPTF Fittings

The 9007BSPP to NPTF fitting is generally constructed from robust materials such as stainless steel, brass, or carbon steel. These materials are selected for their ability to withstand high pressures and resist corrosion, making them ideal for hydraulic applications. The choice of fitting material should be based on the specific environment and application requirements.

For instance, stainless steel 9007BSPP to NPTF fittings are often preferred in corrosive environments, such as marine or chemical applications, where durability is paramount. On the other hand, brass fittings may be used in applications where corrosion resistance is beneficial but not critical.

Selecting the Right 9007BSPP to NPTF Fitting

When choosing a 9007BSPP to NPTF fitting, several factors should be considered, including pressure rating, temperature range, and material compatibility. Different industries and applications come with unique requirements, so the fitting must meet these specifications to ensure reliability and safety.

Moreover, it is essential to ensure that the fitting size matches the components being connected. Fittings that are too large or too small can lead to leaks or catastrophic system failures. Always verify that the fitting is appropriate for the specific application at hand.

FAQs:

1. What is the primary purpose of a 9007BSPP to NPTF fitting?

The primary purpose of a 9007BSPP to NPTF fitting is to connect components with British Standard Pipe Parallel (BSPP) threads to those with National Pipe Tapered Fuel (NPTF) threads, ensuring compatibility between British and American hydraulic systems.

2. What are the main differences between BSPP and NPTF fittings?

BSPP fittings feature straight threads that require additional sealing methods (like O-rings), while NPTF fittings have tapered threads that create a dry seal by compressing against one another. This fundamental difference affects how each fitting is installed and sealed.

3. In which industries are 9007BSPP to NPTF fittings commonly used?

These fittings are commonly used in industries such as manufacturing, automotive, aerospace, and plumbing, where hydraulic and pneumatic systems are prevalent, and components from different thread standards need to be integrated.

4. How do I install a 9007BSPP to NPTF fitting correctly?

To install a 9007BSPP to NPTF fitting correctly, ensure the threads are properly aligned and tightened securely. For the BSPP end, use an appropriate sealing material like an O-ring, while the NPTF end relies on its tapered design for sealing without additional materials.

5. What materials are commonly used in 9007BSPP to NPTF fittings?

These fittings are typically constructed from robust materials such as stainless steel, brass, or carbon steel, chosen for their ability to withstand high pressures and resist corrosion in various environments.

Conclusion

The 9007BSPP to NPTF fitting is an essential component in industries where there is a need to integrate British and American thread standards. Whether in hydraulic systems, plumbing, or fuel lines, this fitting provides a dependable and efficient solution for connecting threads that would otherwise be incompatible. By comprehensively understanding the differences between BSPP and NPTF threads, along with the critical nature of thread compatibility, you can significantly enhance the success of your projects and operations.

Proper selection, installation, and maintenance of 9007BSPP to NPTF fittings are crucial for achieving secure, leak-proof connections. With the right materials and best practices, these fittings can help ensure your system operates efficiently and safely, regardless of the application.